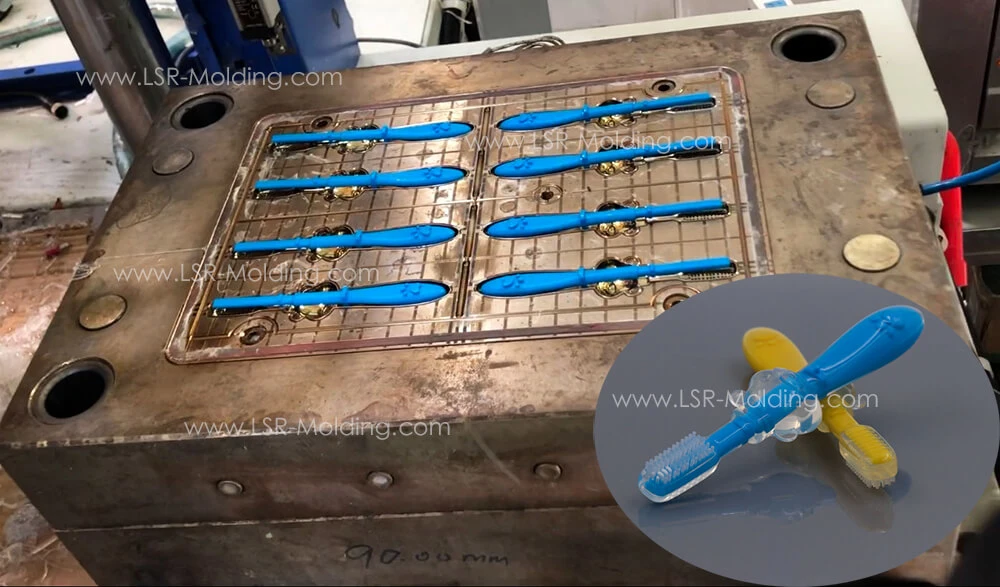

Liquid Silicone Injection Mold for Medical Products/Baby Parts

Precision LSR Injection Mold for Liquid silicone parts/products. Description: Two forming ways: Vertical and Horizontal ;

Basic Info.

| Model NO. | MTR-05 |

| Certification | CE, RoHs |

| Mould Life | >1000000 times |

| Warranty | 5 Years |

| Customized | Customized |

| Forming | Injection |

| Injection Direction | Vertical or Horizontal |

| Mold Materials | LSR |

| Transport Package | Wooden Boxes |

| Specification | CE |

| Trademark | Better |

| Origin | Xiamen, China |

| Production Capacity | 45 Sets/Month |

Product Description

Precision LSR Injection Mold for Liquid silicone parts/products.Description:

Two forming ways: Vertical and Horizontal

· Class 100,000 Clean Room· Two-Shot· Overmolding

Unique Silicone Properties:

· Anti-Microbial· Extreme Temperature Range· Flexible· Durable· Superior Chemical Resistance· Transparent· Ease of Sterilization· Superior Dielectric Insulation

Our Advantage:

1. Precision Mold-Making Technology (Since 1998)

2. Competitive Price: Origin Manufacturer.

3. Five experienced designers (two of them joined better since 2000 years): offer technology/production/design/artwork support etc.

4. Production and Test strictly according to ISO9001.

5. Complete Production Plant, Equipment, Environment

1. Five Plants: Mold-Making, Silicone Rubber Compressive, Plastic Injection, LSR Injection, and Assembly Plants.

2. Mold-Making Equipment: CNC, Mirror EDM, EDM, Slowspeed Wire Cut M/C and other auxiliary equipment etc.

3. Production Equipment: 15 Sets Rubber Compressive Machines, 8 Sets Haitian Plastic Injection Machines, 2 Sets LSR Injection Machines.

4. Test Equipment: 3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc.

5. Dust-free Environment: LSR injection Machines, 3 Sets Rubber Compressive Machines, and Assembly Line in 100,000 rating Dust-free Plants.

6. Fast-reaction Organization: Such as, One morning, Our Customer tell two precision rubber parts for smart cell phone need to revived, and ask we to send revived rubber samples to them at that day. At last, we made it at that day.

You may also like

Send inquiry

Send now